MyAccount loginContactKarrierHU|DE

MyAccount loginContactKarrierHU|DE Surface-mount technology

About us

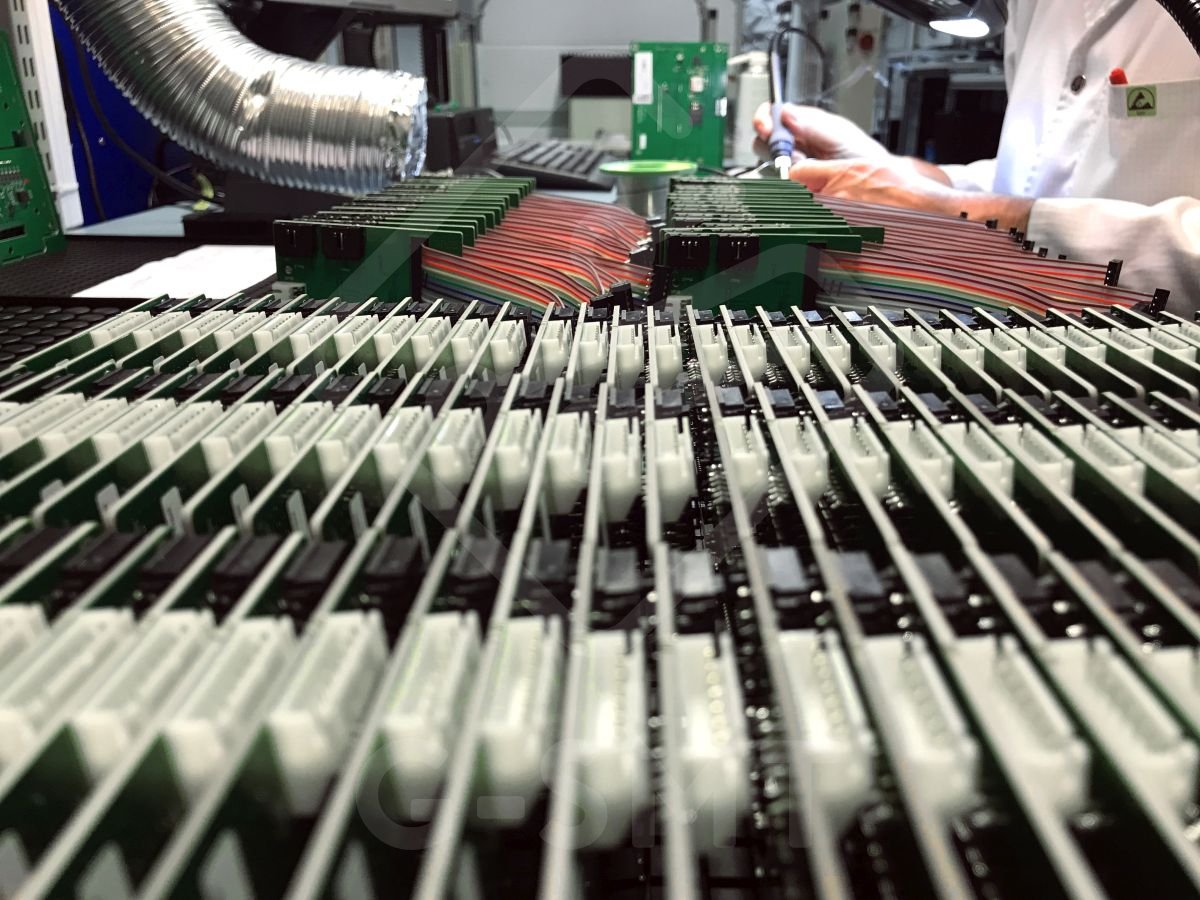

Our company installed its first SMT production line in early 2015. Our company members decided to set up their own production lines after having spent more than 10 years in car electronics manufacturing.

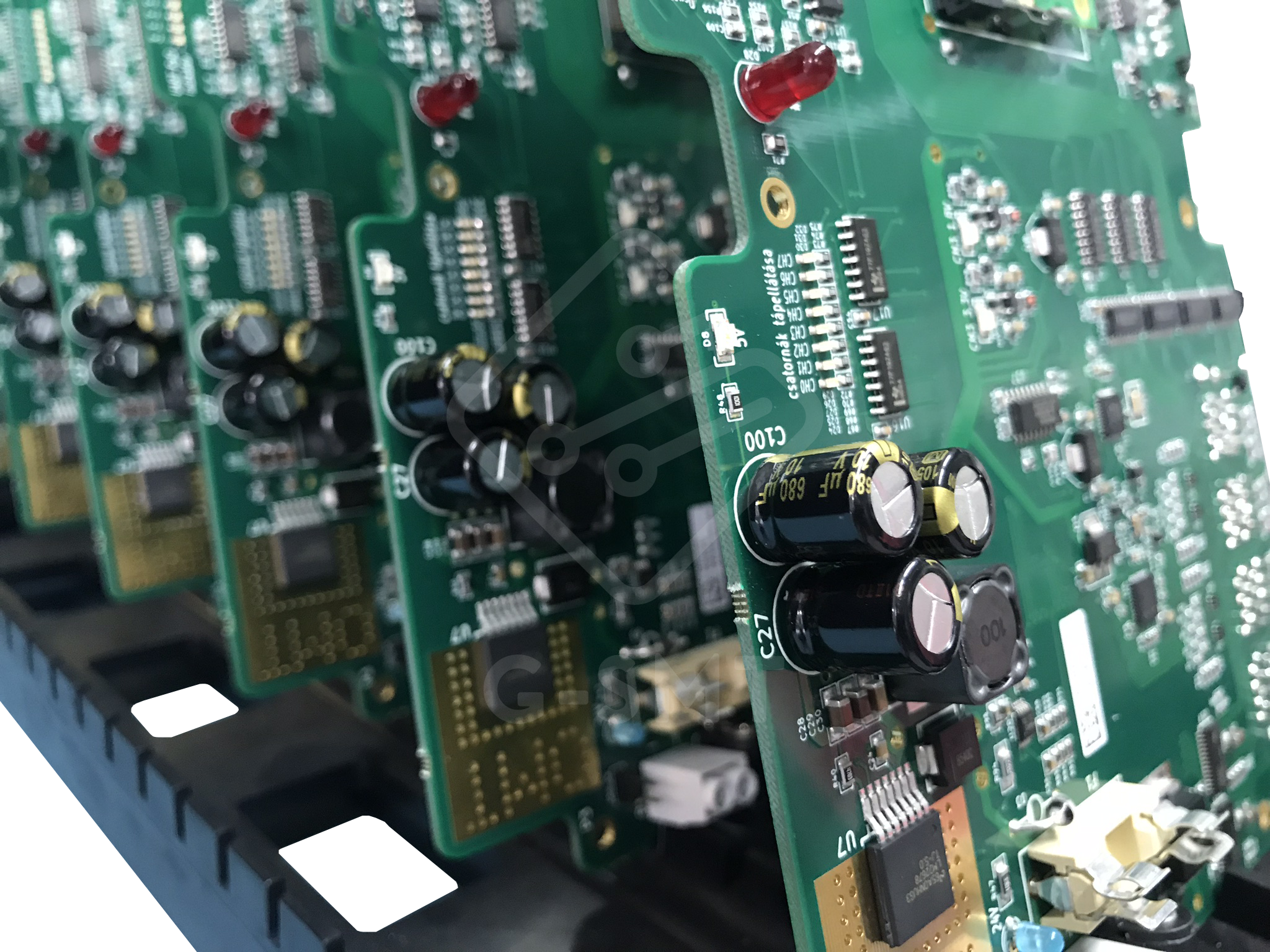

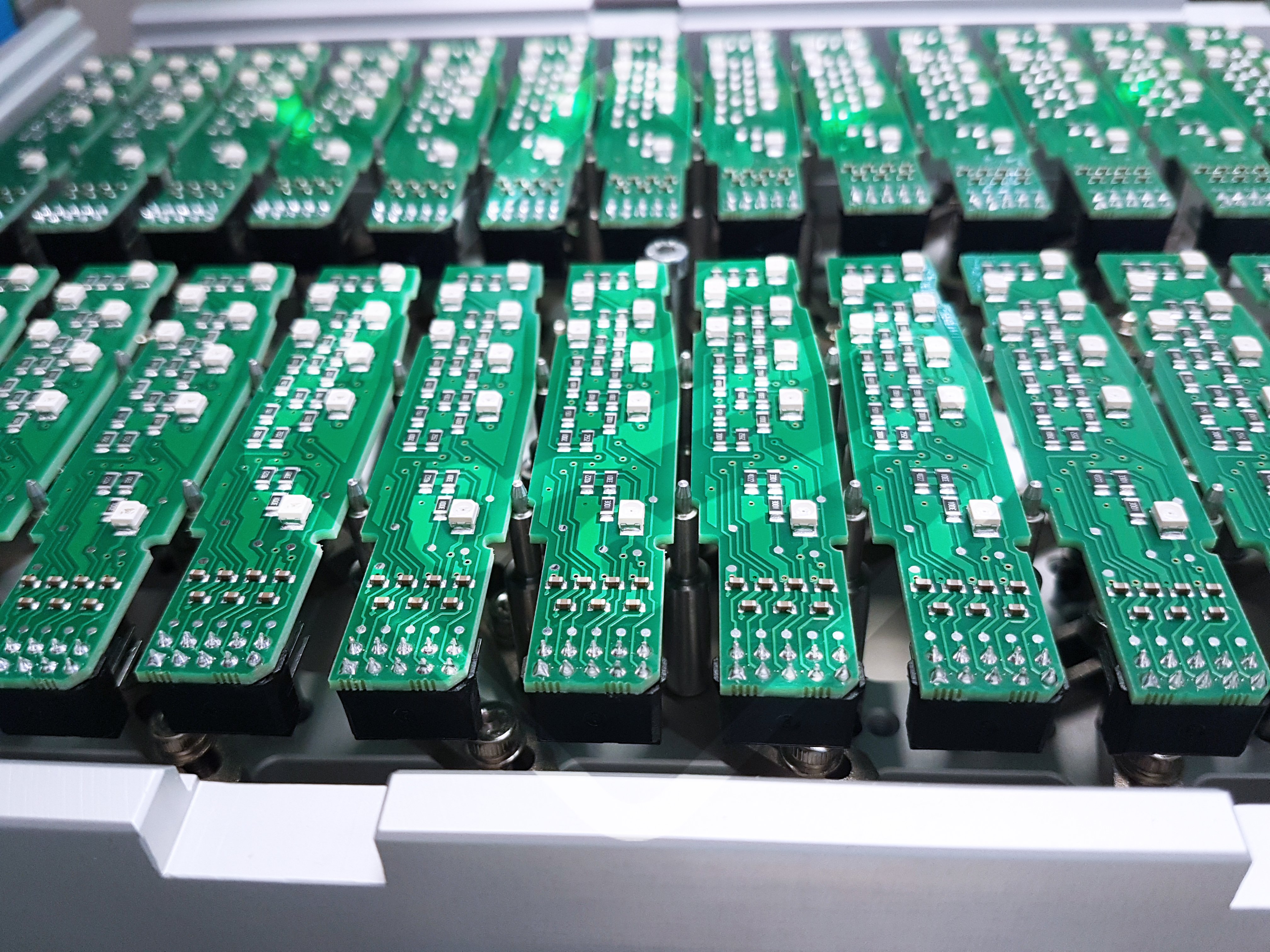

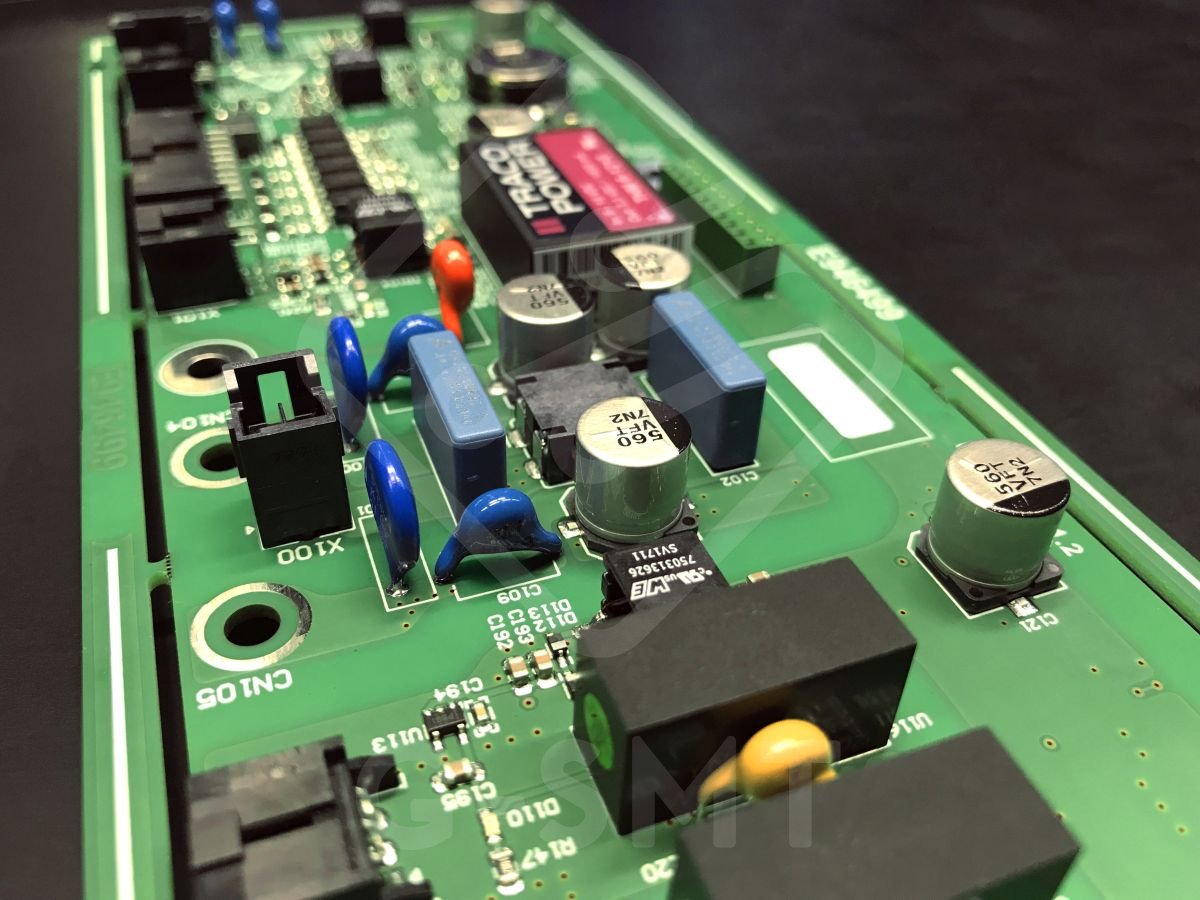

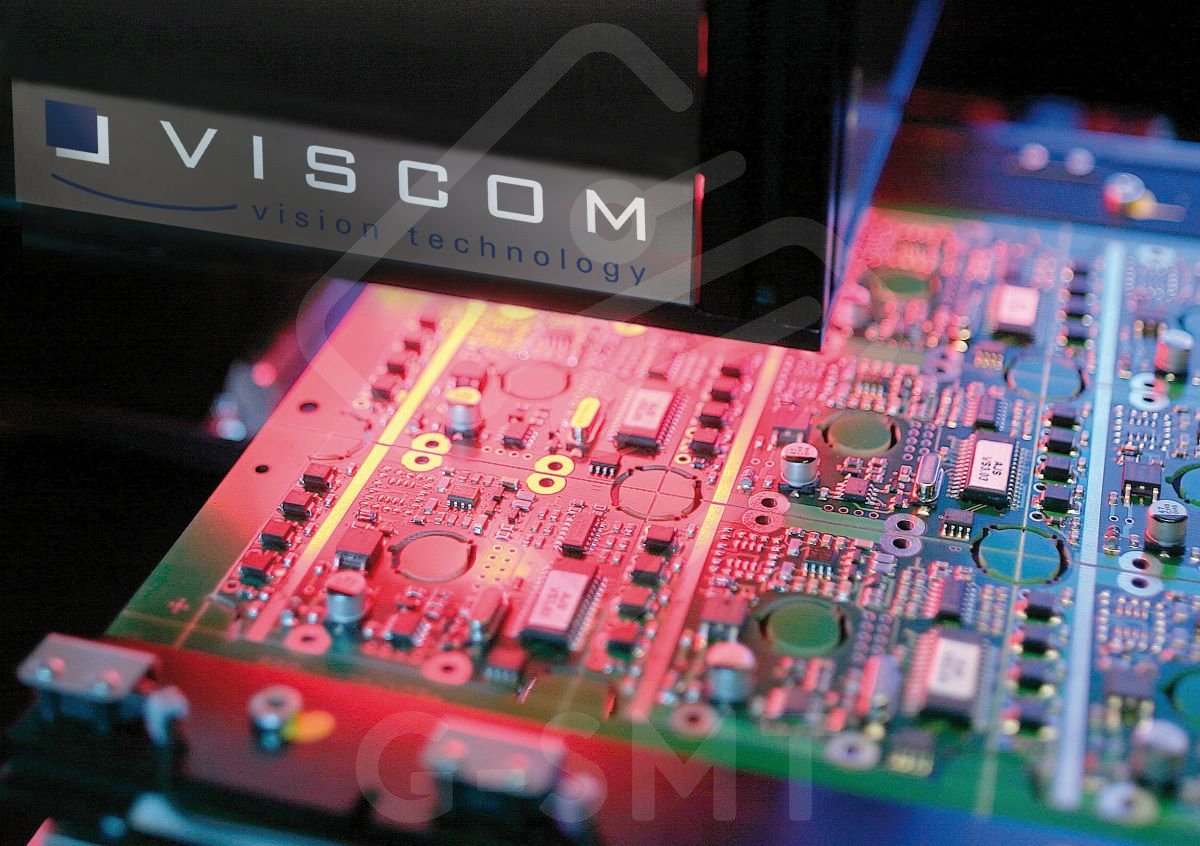

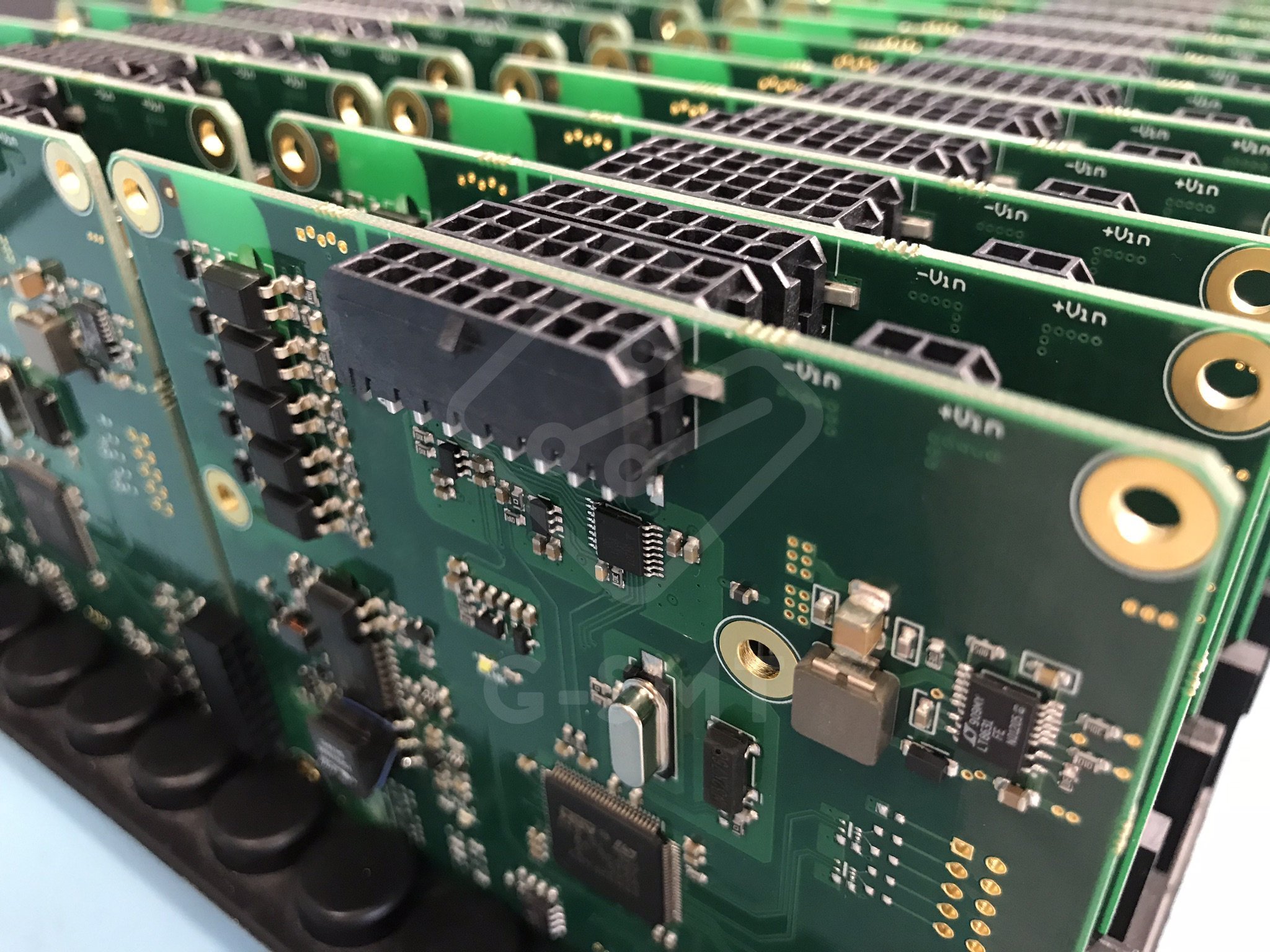

Our main profile is the manufacturing of electronic circuit boards, SMT mounting, cable assembly, BGA repair, and x-ray inspections. In addition, we undertake the manufacturing of complete prototypes, from SMT to final mounting and testing.

The professional competence and personality of our staff members makes it possible for them to provide support to our partners by using their experience gathered in the field of SMT processes; whether it is contracted technological advisory or simple recommendations concerning manufacturability, quality or economy.

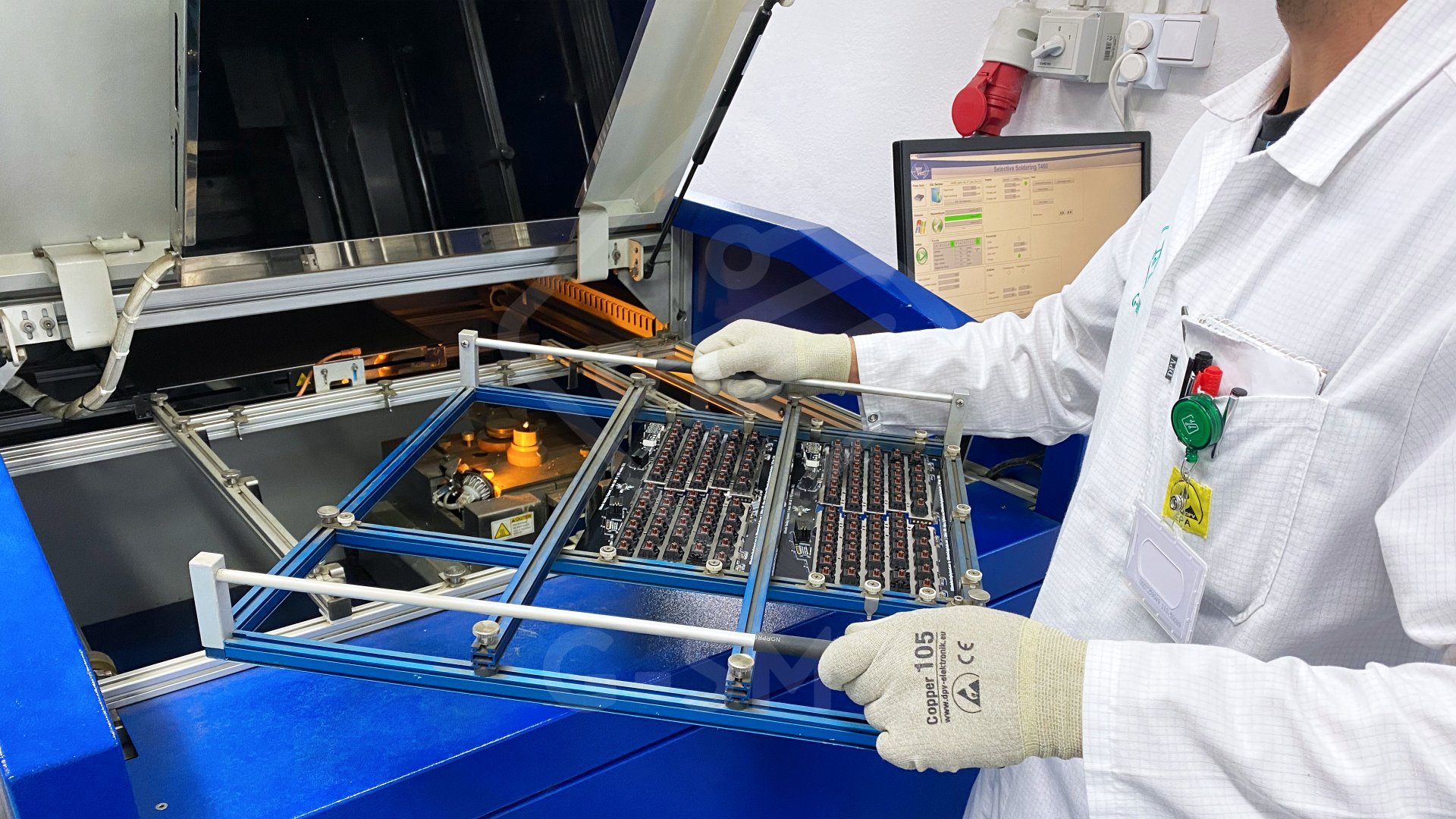

We are currently planning on installing an SMT line suitable for large-batch manufacturing, in addition to our flexible production line suitable for small-batch manufacturing. The conditions of our machines and the tidiness of our environment reflects our level of commitment.

Our team

Quality - flexibility - affordability

Our purpose is to have satisfied partners and long-term partnerships, which we intend to achieve by being conscious of quality, assuming full responsibility for our work, by being flexible and offering affordable prices.

Our company policy Code of ConductESD protected area

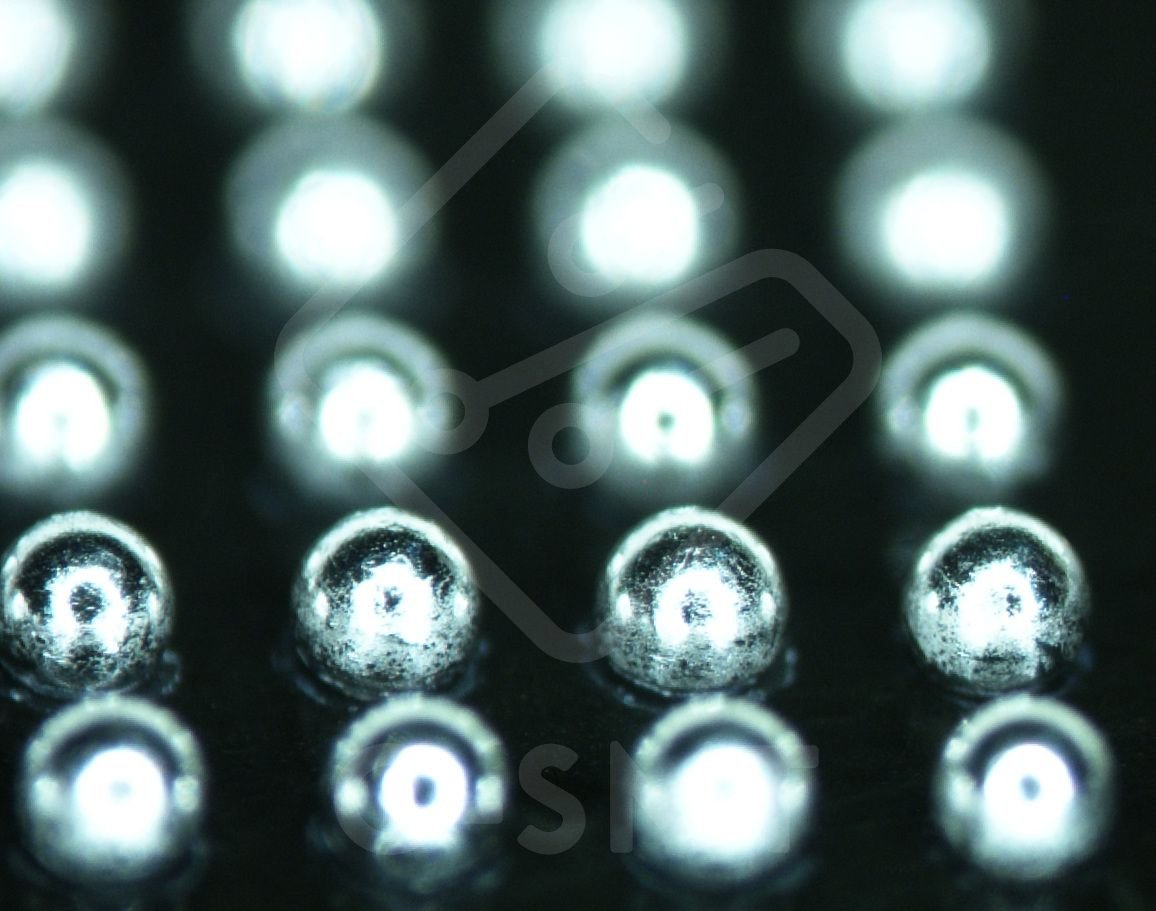

If statically charged materials are approached to each other, an extremely fast electric charge starts to flow to balance the potential difference, which sometimes can be perceived in the form of sparks and unpleasant bites. Electrostatic discharge (ESD) can sometimes take place between the charged materials without even being noticed, causing serious problems in the electronics industry. This is because electronic equipment and parts are extremely sensitive to electrostatic discharge, and so the use of antistatic materials and ensuring an ESD protected environment (ESDS) is of paramount importance during manufacturing, transport and repair.

Accordingly, both our manufacturing plant and storage facilities are ESD protected. The full handling process, from the arrival of parts through the manufacturing processes, to the handling and shipment of finished products, takes place on ESDS areas. Particular attention is paid to using ESDS packaging technology also during shipment, to provide for the maximum protection of finished products. The units requiring particular precautions are also marked with a standard distinguishing sign throughout the area of the site.

Functionalities of the MyAccount system

- You can become our registered partner through the GMAS (G-SMT MyAccount System) rwhere you can comfortably share with us your manufacturing designs as well as any files, data and work processes necessary for manufacturing.

- As a partner, you can check the quantity of the parts and finished products we have on stock for your company. From the products registered in the system, you can compile an order package, and – with the manufacturing simulation – you can establish the necessary number of parts.

- In case of an order, you can monitor the current status and the schedule of the manufacturing process online.

- You can share your information and comments regarding product manufacturing with us, as our staff can be contacted at any time in this connection.

E-learning

A G-SMT elkötelezte magát amellett, hogy elősegítse a tudásmegosztást az elektronikai gyártás területén érintett partnerek és munkavállalók között. Ez a gyakorlat rendkívül előnyös, mert lehetővé teszi az iparág szereplői számára, hogy naprakészen maradjanak a legújabb technológiákkal, gyártási módszerekkel, elvárások, szabványok és ipari trendekkel kapcsolatban. A folyamatos tanulás és tapasztalatcsere növeli a munkaerő rugalmasságát és adaptációs képességét, így segítve őket abban, hogy hatékonyabban reagáljanak a piaci változásokra és a technológiai előrelépésekre.

A tudásmegosztás továbbá kulcsfontosságú a minőség javítása és a hibák csökkentése érdekében. Amikor a partnerek és munkavállalók megosztják egymással a legjobb gyakorlatokat és megoldásokat, az egész szervezet, beszerzési láncolat profitál belőle, hiszen így a gyártási folyamatok optimalizálása és a termelékenység növelése érhető el. A megosztott tudás révén a munkatársak képesek lesznek jobban megérteni a különböző folyamatokat és azok összefüggéseit, ami hozzájárul a hatékony problémamegoldáshoz és az innovációhoz.

Contact

Toldi Miklós utca 5.

Miskei út 23.

Show in map »