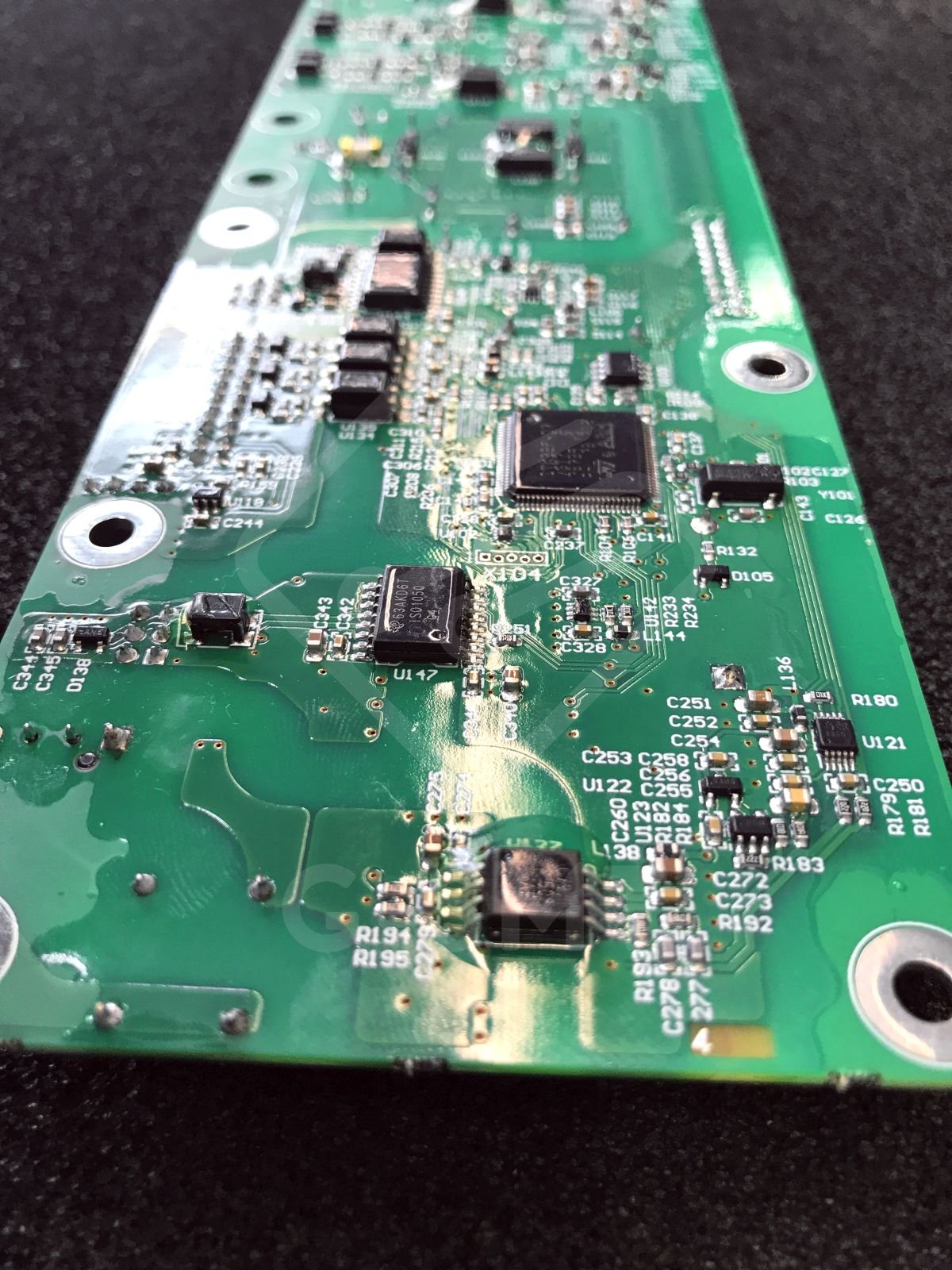

PCB washing: with our DCT INJET semi-automatic equipment, the flux residues generated during manual or wave soldering as well as other smaller impurities can be completely removed from the PCB surface, thereby ensuring long-lasting and high-quality varnishing.

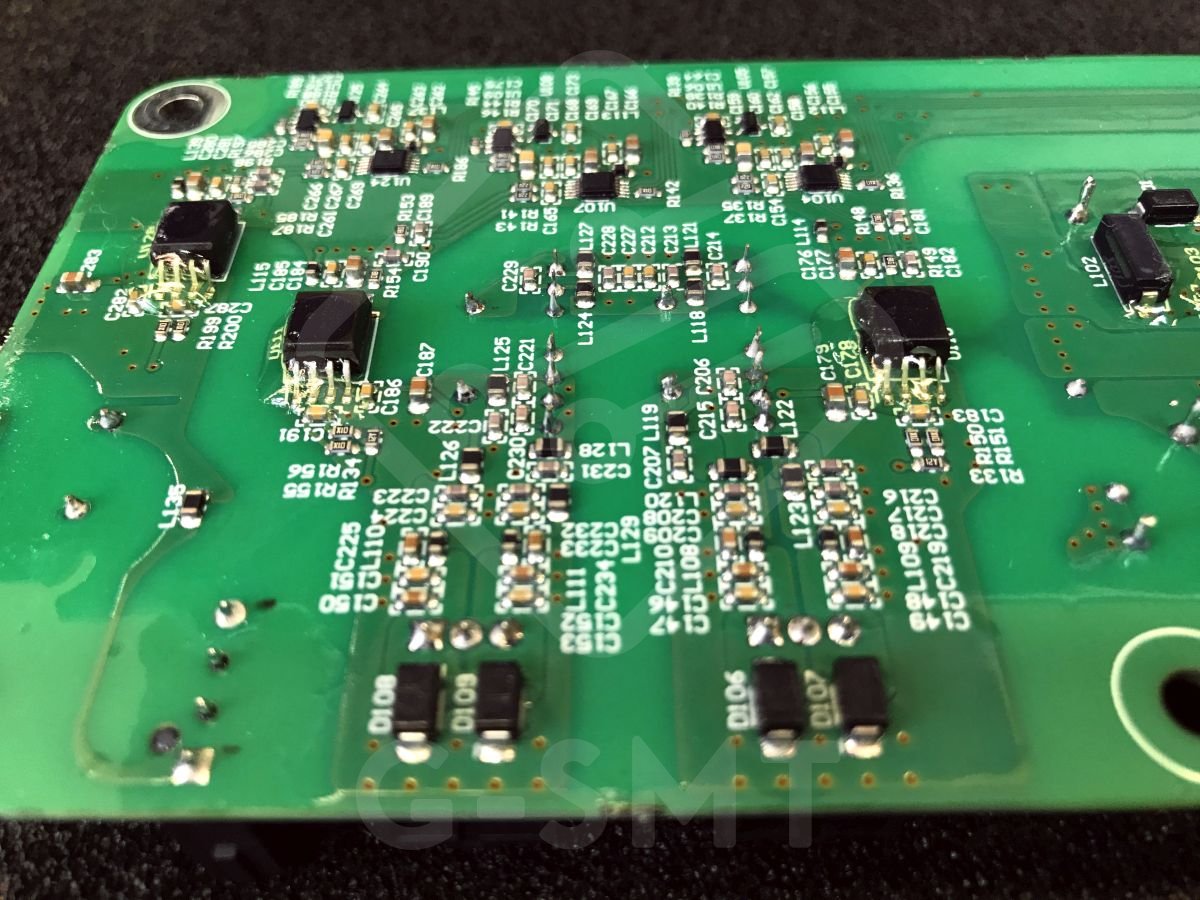

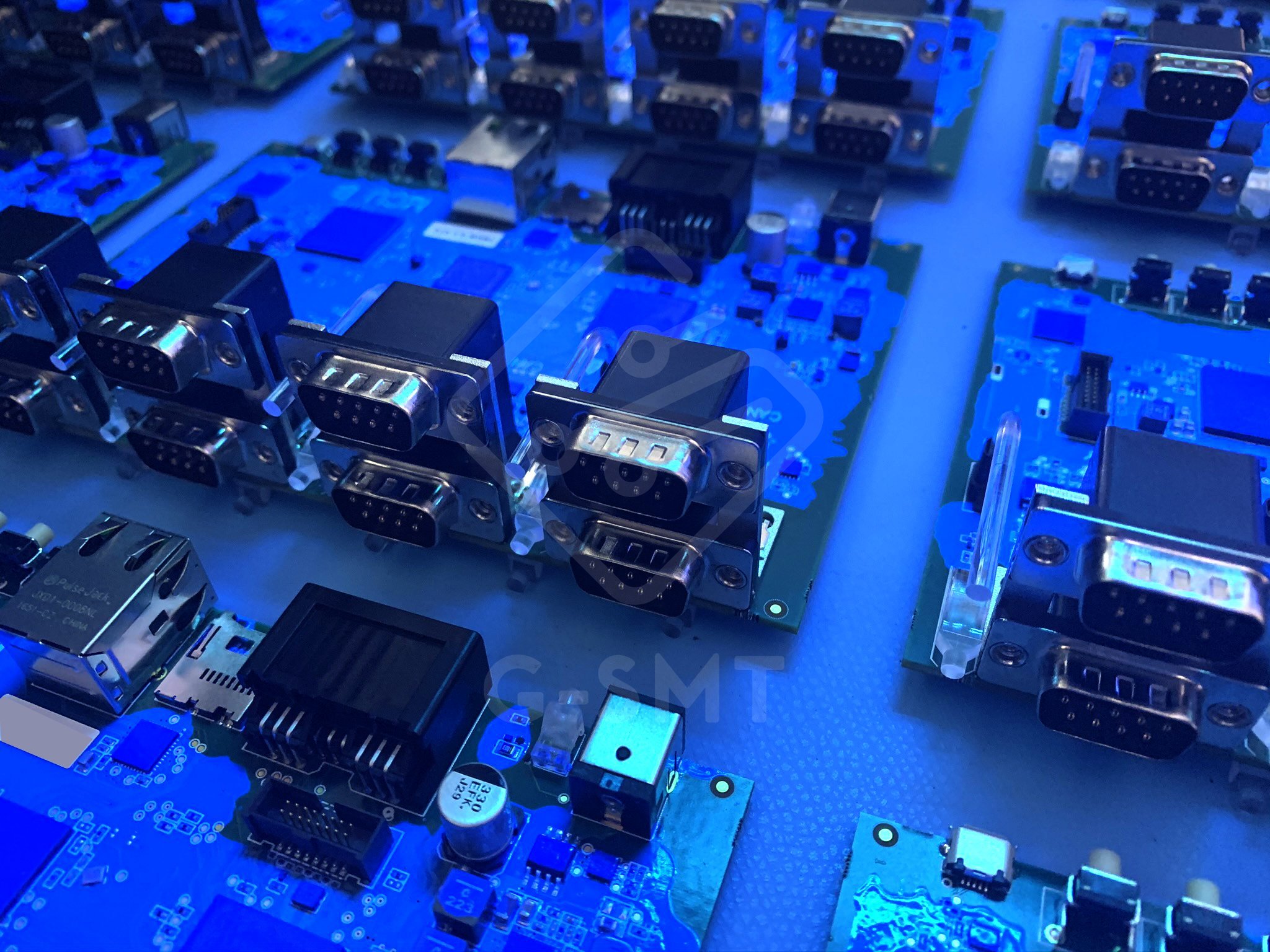

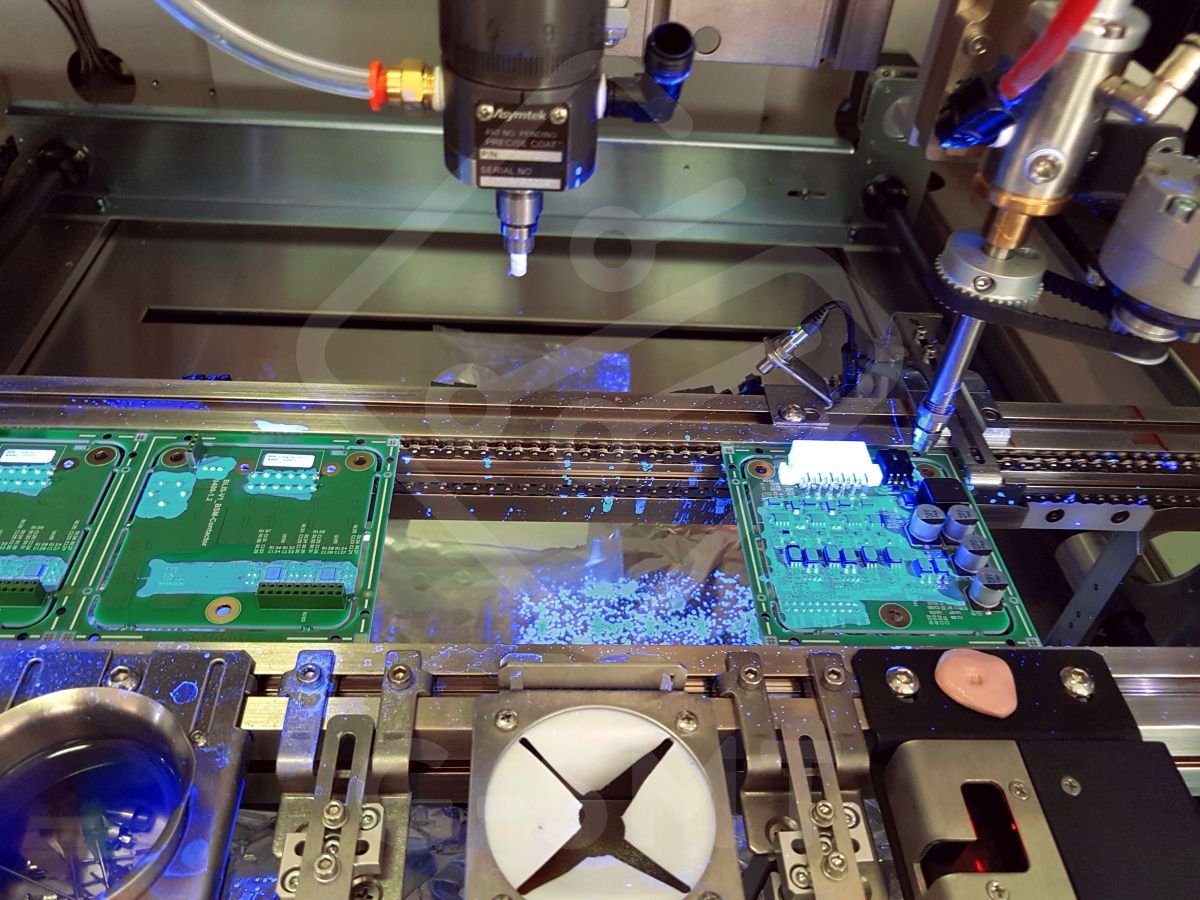

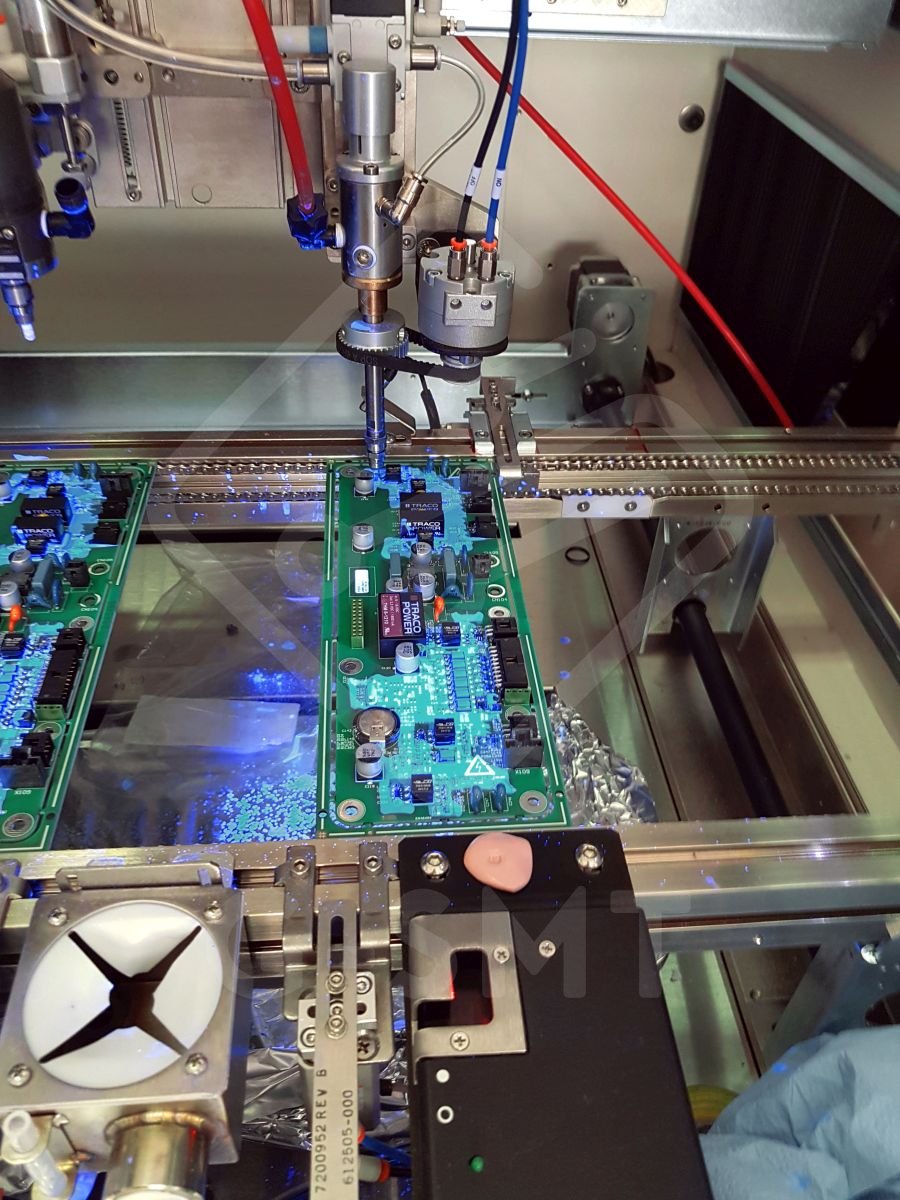

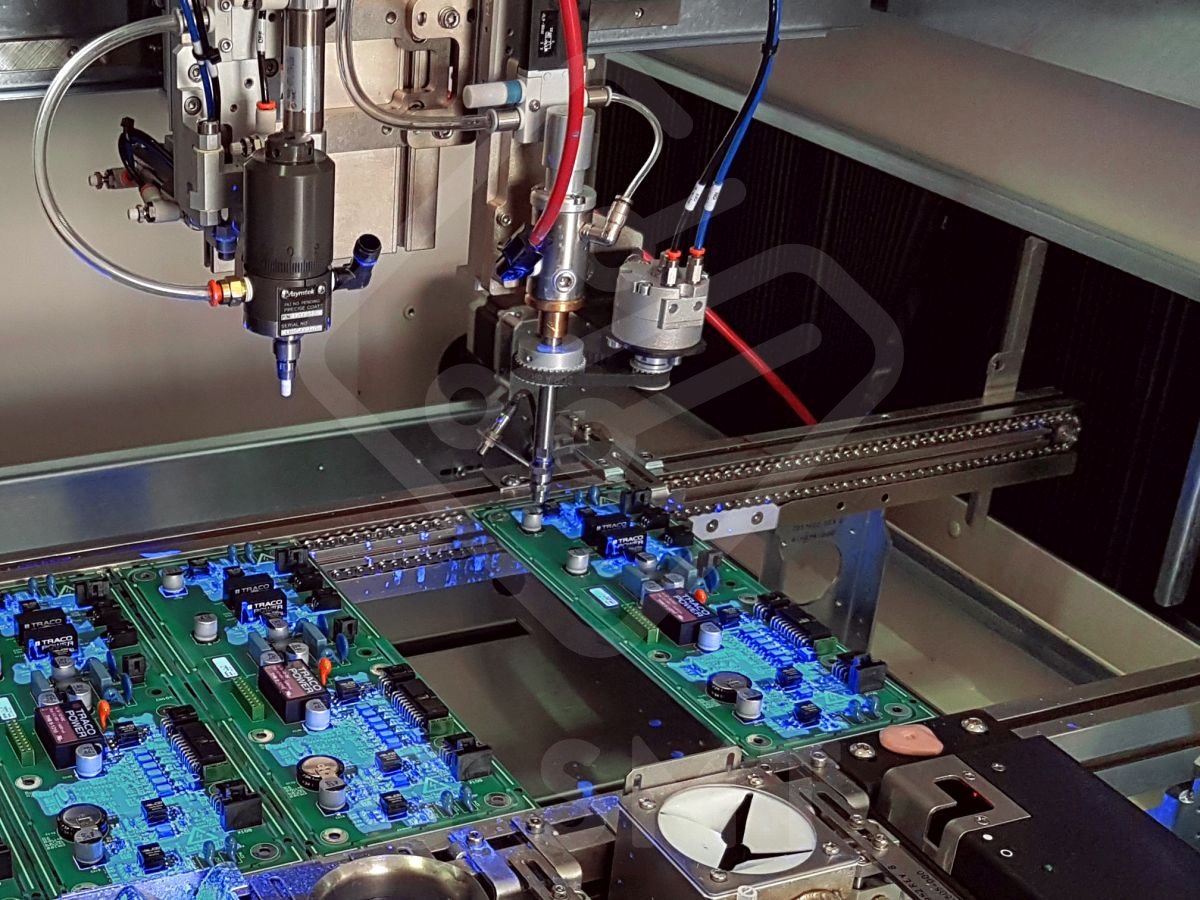

Coating: You can choose from among several varnishing options according to your needs. Acrylic and silicone-based materials with different micron thickness, which, if applied to the product, prevent the corrosion resulting from extreme usage conditions as well as other harmful chemical processes.

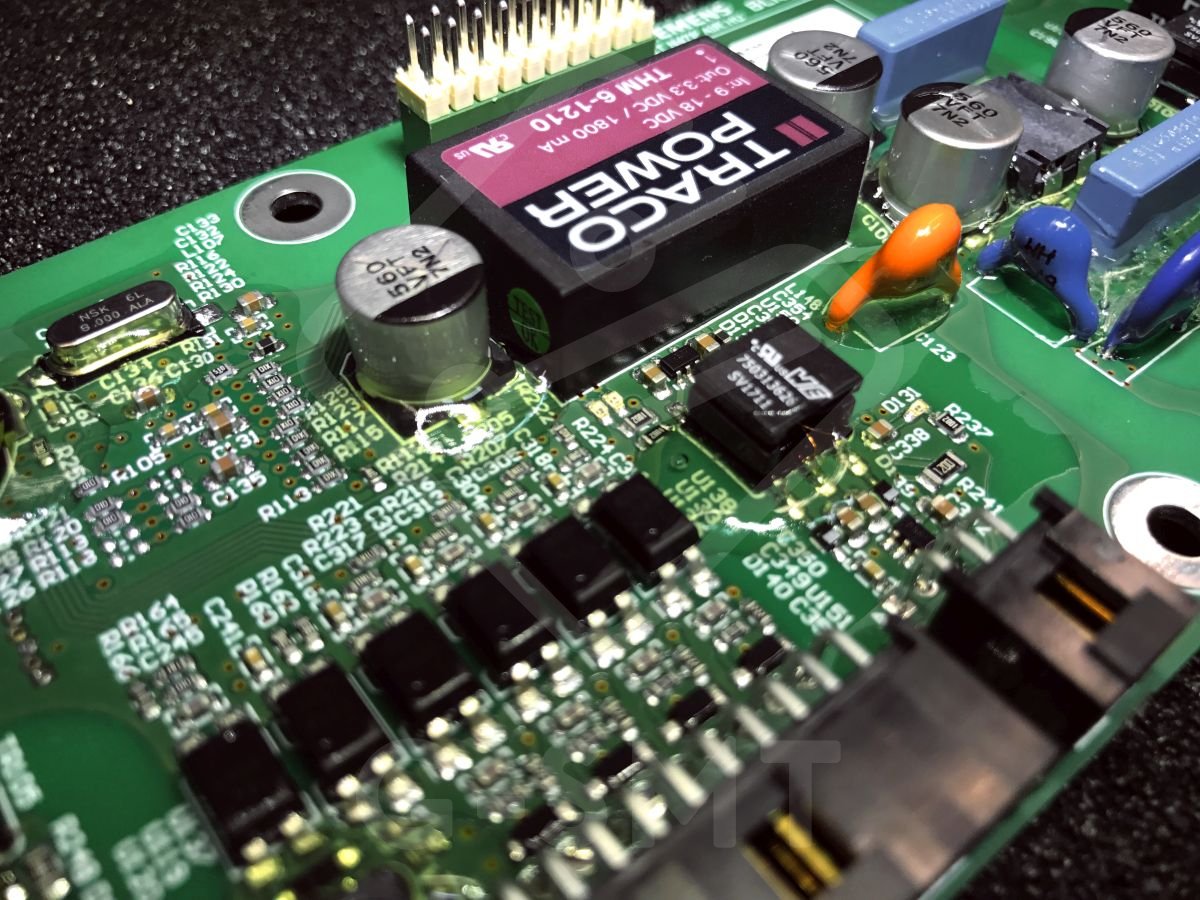

Gluing, fixture: We can equip different size of SMT (e.g. socket) ad TH (large size condenser) parts with extra physical fixture, which can relieve the soldering of the parts in case of physical load. It is recommended for large parts and for products exposed to high acceleration.